There are an estimated 14 million oil-fired boilers in the EU, a huge market worth 6 billion euro if someone finds a way to substitute the oil-fired boilers with a smarter technology that is cleaner to the planet and more efficient in saving energy.

This new technology can be a fuel cell powered micro unit for combined heat and power generation (FC µCHP). And this someone can be the new research center 4M at DTU Energy Conversion, Technical University of Denmark, which coordinates the research efforts of eight Danish and international universities and research institutes as well as three Danish companies from the private sector.

4M stands for Mechanisms, Materials, Manufacturing and Management, and the goal of the 4M research center is to do world class fundamental research on high temperature proton exchange membrane fuel cells (HT-PEM) fuel cells and in doing so help and promote the commercialization of HT PEM fuel cells in the near future.

The PEM-technology is not new. Low temperature PEM-cells operate at 80-100 degrees Celsius, making the PEM-cells very useable in cars. But while there is a lot of research in PEM going on across the world, concentrating on low temperature PEM, only a small number of groups in the world do research on high temperature PEM (HTPEM) that operates at temperatures up to 200 degrees Celsius.

“HTPEM is of less interest for car-manufacturers, because the constant turn on/off is challenging for the long term durability of HTPEM. But HTPEM is promising for use in houses, where the power consumption is more steady, and DTU has a huge knowhow of both low temperature and high temperature PEM-cells”, says Associate professor and Center Manager of 4M Centre, Qingfeng Li from DTU Energy Conversion.

Consecutive Danish governments and DTU have prioritized research in PEM fuel cells for the past 10 years, making Denmark the leading country in the world on PEM. Also Denmark hosts three firms specialized in PEM fuel cells, the companies Danish Power Systems, Serenergy and IRD Fuel Cells, which all participate in the 4M Centre.

“DTU Energy Conversion is internationally known for being in the lead on HT-PEM technologies, so it is natural for most that we take on the challenge of leading the 4M-project”, says Qingfeng Li.

The greatest objective of 4M is the gathering of more knowledge on PEM cells, as PEM cells still are too expensive and not durable enough for market penetration.

A PEM unit for a car has a theoretical lifespan of 5000 working hours, but most spend only 1-2 hours a day in cars and drives to service each 20.000 kilometers. With an average of 75 km/hour, you only spend 3000 hours in a car before next service. The medium term development goal for a household HTPEM-unit is approx. 40.000 hours. However, that’s not enough for a commercial breakthrough, despite 40.000 work hours being five years.

“We have working and functional HTPEM-units on the market, but when you buy an oil-boiler, you know it will last for at least 10 years. We have no such knowledge of the duration of the HTPEM-units. Our development goal is 40.000 hours, but we are not there yet, and we keep inventing new materials, new ways of doing things, and we can’t wait 5 years before seeing, if it works”, says Qingfeng Li.

Denmark and the European Union can’t wait for years either. Both have the agendas of halving the output of CO2 and lowering dependency on fossil fuels and they want to use the fuel cell technology to do so. This is why 4M Centre has been established with financial backing from the Danish Council for Strategic Research (DSF). The budget is 43.7 mio. DDK, of which 31 mio. are from DSF; 7 mio. DKK of the DSF funding go to DTU.

“We have had many PEM-projects with technological goals, but this one is different. This time we have five years to gather fundamental knowledge and become a great stepping stone, from which we along the way can start a lot of spinoff projects to make use the knowledge for manufacturing and commercialization of the HT PEMFC-technology,” says Qingfeng Li.

The 4M research center last until 2018.

For information, contact Center Manager Qingfeng Li, DTU Energy Conversion, Ph. +45 4525 2318, e-mail: qfli@dtu.dk

|

Download the pictures here

|

|

|

|

|

|

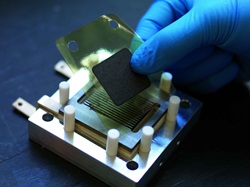

HT PEM-fuel cells can work on "unclean" and easily manageable fuels like methanol or methane

|

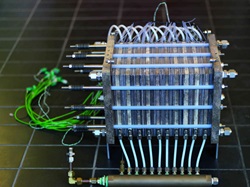

A PEM fuel cell stack consists of several PEM fuel cells connected electrically in series

|

Researcher Lars Clemann from DTU Energy Conversion tests PEM cells

|

The focused funding from the Danish Government is not the only reason for Denmark to be world leader on PEM fuel cell-technologies. Another big reason is the unique Danish way of doing research.

Four universities research in PEM. Aalborg University (AU), University of Copenhagen (KU), the University of Southern Denmark (SDU) and Technical University of Denmark (DTU), but they do complimentary research.

DTU do research on materials, the polymer, the membranes and the cells. KU researches catalysts. Aalborg do research on the system level, i.e. simulation and modeling. And SDU researches materials and evaluation in cell assembling.

“We have collaborated this way for years. It was not planned or coordinated like this, but each group sort of found their role in a typically Danish way. There is no competition, well of course in a friendly sort of way, but we are not enemies. Not like in some larger countries, where universities overlap and this way have to compete a lot more over the funding. We help each other”, says Qingfeng Li.

And the Danish companies do the same. Danish Power Systems make the components, IRD Fuel Cells and Seerenergy make the stacks of fuel cells, but there is no direct competition, so no one feels threatened by others. If a company has a technical problem, they are not secretive and help each other. Just like the universities. This is one of the major reasons that Denmark is in front on PEM fuel cell technologies.